Table of Contents

Benefits of Using High-Quality Lifting Equipment in Warehouse Operations

In the fast-paced world of warehouse operations, efficiency and safety are paramount. One way to achieve both of these goals is by investing in high-quality lifting equipment. Whether you are a small business or a large corporation, having the right tools for the job can make a significant difference in your bottom line. In this article, we will explore the benefits of using high-quality lifting equipment in warehouse operations.

First and foremost, high-quality lifting equipment can improve the overall efficiency of your warehouse operations. By investing in equipment that is designed to handle heavy loads and operate smoothly, you can reduce the time it takes to move products from one location to another. This can lead to increased productivity and ultimately, higher profits for your business. Additionally, high-quality lifting equipment is often more durable and reliable than lower-quality alternatives, reducing the risk of breakdowns and costly repairs.

Another benefit of using high-quality lifting equipment in warehouse operations is improved safety. When working with heavy loads, it is essential to have equipment that is designed to handle the task safely. High-quality lifting equipment is often equipped with safety features such as overload protection and emergency stop buttons, reducing the risk of accidents and injuries in the workplace. By investing in equipment that prioritizes safety, you can create a more secure working environment for your employees and reduce the likelihood of costly workplace incidents.

Furthermore, high-quality lifting equipment can help to optimize the use of space in your warehouse. By investing in equipment that is designed to lift and move heavy loads efficiently, you can make better use of vertical space in your facility. This can help to maximize storage capacity and improve the overall organization of your warehouse. By utilizing high-quality lifting equipment, you can create a more streamlined and efficient workflow that allows you to make the most of your available space.

In addition to improving efficiency, safety, and space utilization, high-quality lifting equipment can also help to reduce operating costs in the long run. While the initial investment in high-quality equipment may be higher than lower-quality alternatives, the durability and reliability of these products can lead to significant cost savings over time. By investing in equipment that is built to last, you can reduce the need for frequent repairs and replacements, ultimately lowering your overall maintenance costs.

In conclusion, investing in high-quality lifting equipment for warehouse operations can offer a wide range of benefits for businesses of all sizes. From improved efficiency and safety to optimized space utilization and reduced operating costs, the advantages of using high-quality equipment are clear. By prioritizing quality when selecting lifting equipment for your warehouse, you can create a more productive, safe, and cost-effective working environment for your employees. So, if you are looking to enhance the performance of your warehouse operations, consider investing in high-quality lifting equipment today.

How to Choose the Right Lifting Equipment for Your Warehouse Export Business

When it comes to running a successful warehouse export business, having the right lifting equipment is crucial. Whether you are moving heavy pallets of goods or loading containers for shipment, having the proper equipment can make all the difference in efficiency and safety. With so many options available on the market, it can be overwhelming to choose the right lifting equipment for your specific needs. In this article, we will discuss some key factors to consider when selecting lifting equipment for your warehouse export business.

One of the first things to consider when choosing lifting equipment is the weight capacity. It is important to know the maximum weight that the equipment can safely lift in order to avoid accidents and damage to goods. Make sure to assess the heaviest loads that you will be lifting on a regular basis and choose equipment that can handle those weights with ease.

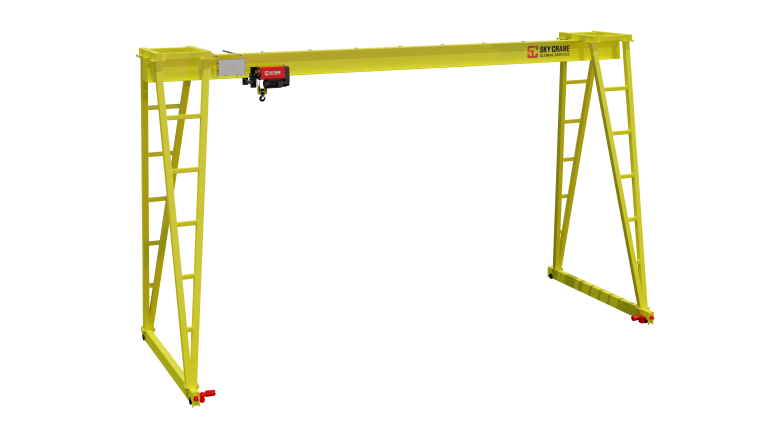

Another important factor to consider is the type of lifting equipment that will best suit your needs. There are various types of lifting equipment available, including forklifts, pallet jacks, hoists, and cranes. Each type of equipment has its own advantages and limitations, so it is important to choose the one that is best suited for the tasks you will be performing in your warehouse.

In addition to weight capacity and type of equipment, it is also important to consider the size and layout of your warehouse. Make sure to choose lifting equipment that can maneuver easily in the space available and can reach all areas where lifting will be required. Consider factors such as aisle width, ceiling height, and any obstacles that may impede the movement of the equipment.

Safety is another crucial factor to consider when choosing lifting equipment for your warehouse export business. Make sure to select equipment that meets all safety standards and regulations, and provide proper training for employees who will be operating the equipment. Regular maintenance and inspections should also be conducted to ensure that the equipment is in good working condition and safe to use.

| Serial Number | Product |

| 1 | LD electric single beam crane |

| 2 | Universal gantry crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Cost is also an important consideration when choosing lifting equipment for your warehouse export business. While it may be tempting to opt for the cheapest option, it is important to consider the long-term costs of maintenance and repairs. Investing in high-quality equipment may cost more upfront, but it can save you money in the long run by reducing downtime and the risk of accidents.

In conclusion, choosing the right lifting equipment for your warehouse export business is a crucial decision that can impact the efficiency and safety of your operations. Consider factors such as weight capacity, type of equipment, warehouse layout, safety, and cost when making your decision. By taking the time to carefully assess your needs and choose the right equipment, you can ensure that your warehouse export business runs smoothly and successfully.

Top Safety Tips for Operating Lifting Equipment in a Warehouse Setting

Lifting equipment plays a crucial role in warehouse operations, allowing for the efficient movement of heavy goods and materials. However, operating this equipment comes with its own set of risks and challenges. To ensure the safety of workers and the smooth functioning of the warehouse, it is essential to follow proper safety protocols when using lifting equipment.

One of the most important safety tips for operating lifting equipment in a warehouse setting is to ensure that all operators are properly trained and certified. Operating lifting equipment requires specialized skills and knowledge, and only trained individuals should be allowed to operate this machinery. Training should cover not only how to operate the equipment but also how to identify potential hazards and how to respond in case of an emergency.

In addition to proper training, it is essential to regularly inspect and maintain lifting equipment to ensure that it is in good working condition. Regular inspections can help identify any potential issues before they become serious problems, reducing the risk of accidents and injuries. Maintenance should be carried out according to the manufacturer’s guidelines, and any faulty equipment should be taken out of service immediately.

When operating lifting equipment, it is important to always follow the manufacturer’s instructions and guidelines. This includes adhering to weight limits, using the equipment on level ground, and avoiding sudden movements or jerky motions. Failure to follow these guidelines can result in accidents and injuries, so it is crucial to always operate lifting equipment in a safe and controlled manner.

Another important safety tip for operating lifting equipment in a warehouse setting is to ensure that the area is clear of obstacles and other hazards. Before using the equipment, operators should inspect the surrounding area and remove any potential obstructions that could interfere with the operation of the machinery. This includes ensuring that there is enough space to maneuver the equipment safely and that there are no overhead obstacles that could pose a risk.

It is also important to use proper lifting techniques when operating lifting equipment in a warehouse setting. This includes using the correct attachments and accessories, securing the load properly, and maintaining a stable center of gravity. Improper lifting techniques can result in accidents and injuries, so it is essential to always follow best practices when using lifting equipment.

Finally, it is crucial to always wear the appropriate personal protective equipment when operating lifting equipment in a warehouse setting. This includes items such as hard hats, safety goggles, gloves, and steel-toed boots. Personal protective equipment can help protect workers from potential hazards and reduce the risk of injuries in the event of an accident.

In conclusion, operating lifting equipment in a warehouse setting requires careful attention to safety protocols and best practices. By ensuring that operators are properly trained, regularly inspecting and maintaining equipment, following manufacturer’s guidelines, keeping the area clear of obstacles, using proper lifting techniques, and wearing the appropriate personal protective equipment, the risk of accidents and injuries can be minimized. By prioritizing safety, warehouse operators can create a safe and efficient working environment for all employees.