Table of Contents

LDP Electric Single Beam Crane: Customization Options and Benefits

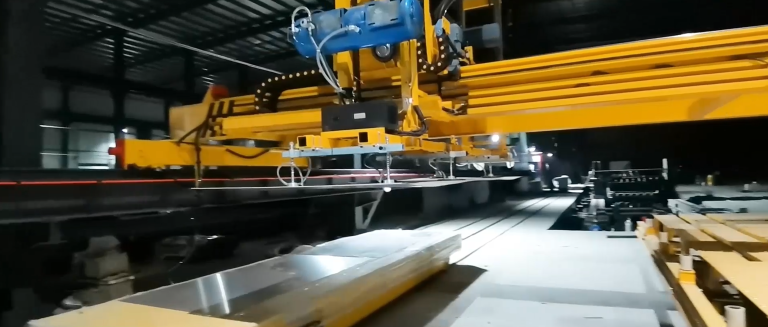

The LDP electric single beam crane has emerged as a vital piece of equipment in various industrial applications, offering a blend of efficiency, reliability, and versatility. One of the standout features of this crane is its customization options, which allow businesses to tailor the equipment to meet their specific operational needs. This adaptability is particularly beneficial in industries where unique lifting requirements and space constraints are prevalent. By collaborating with leading Chinese manufacturers, companies can access a range of customization options that enhance the crane’s functionality and performance.

When considering the customization of the LDP electric single beam crane, it is essential to recognize the various components that can be modified. For instance, the lifting capacity can be adjusted to accommodate different weights, ensuring that the crane can handle the specific loads required by the operation. Additionally, the span of the beam can be customized to fit the dimensions of the workspace, allowing for optimal maneuverability and efficiency. This flexibility in design not only maximizes the crane’s utility but also minimizes the risk of accidents and equipment failure.

Moreover, the customization options extend to the crane’s operational features. Businesses can choose from a variety of control systems, including remote control and pendant control, depending on their operational preferences. This choice enhances user convenience and safety, as operators can manage the crane from a distance, reducing the risk of injury in hazardous environments. Furthermore, manufacturers often provide options for advanced safety features, such as overload protection and emergency stop systems, which are crucial for maintaining a safe working environment.

In addition to functional modifications, aesthetic customization is also available. Companies can select specific colors and finishes that align with their branding or operational environment. This attention to detail not only enhances the visual appeal of the equipment but also fosters a sense of ownership and pride among employees who operate the crane. Such customization options reflect the commitment of Chinese manufacturers to meet the diverse needs of their clients, ensuring that each crane is not only a tool but also a reflection of the company\u2019s identity.

The benefits of customizing the LDP electric single beam crane extend beyond mere aesthetics and functionality. By investing in a tailored solution, businesses can significantly improve their operational efficiency. A crane that is designed to meet specific requirements can reduce downtime, streamline workflows, and enhance productivity. Additionally, customized cranes often lead to lower maintenance costs, as they are built to withstand the unique demands of the environment in which they operate.

Furthermore, working with reputable Chinese manufacturers ensures that companies receive high-quality products that adhere to international standards. These manufacturers often employ advanced technology and skilled labor, resulting in cranes that are not only durable but also equipped with the latest innovations in lifting technology. This commitment to quality and innovation further underscores the advantages of opting for a customized LDP electric single beam crane.

In conclusion, the LDP electric single beam crane offers a wealth of customization options that cater to the diverse needs of various industries. By collaborating with leading Chinese manufacturers, businesses can create a crane that not only meets their specific operational requirements but also enhances safety and efficiency. The ability to tailor both functional and aesthetic aspects of the crane ensures that companies can optimize their investment, ultimately leading to improved productivity and a safer working environment.

Top Chinese Manufacturers of LDP Electric Single Beam Cranes

In the realm of material handling equipment, LDP electric single beam cranes have emerged as a vital solution for various industrial applications. These cranes are particularly valued for their efficiency, versatility, and ability to operate in confined spaces. As industries continue to evolve, the demand for customized solutions has surged, prompting manufacturers to innovate and tailor their products to meet specific client needs. Among the leading players in this sector, several top Chinese manufacturers have distinguished themselves through their commitment to quality, advanced technology, and customer-centric approaches.

One of the foremost manufacturers in this field is Dongqi Crane, renowned for its extensive range of lifting equipment, including LDP electric single beam cranes. With a strong emphasis on research and development, Dongqi Crane has successfully integrated cutting-edge technology into its products, ensuring that they meet international safety and performance standards. Their ability to customize cranes according to client specifications has made them a preferred choice for businesses seeking tailored solutions. Furthermore, their robust after-sales service and support enhance customer satisfaction, solidifying their reputation in the market.

Another prominent manufacturer is Weihua Group, which has established itself as a leader in the crane manufacturing industry. Weihua Group’s LDP electric single beam cranes are characterized by their high load capacity and durability, making them suitable for a wide range of applications, from manufacturing to logistics. The company\u2019s commitment to innovation is evident in its use of advanced materials and engineering techniques, which not only improve the performance of their cranes but also extend their lifespan. Additionally, Weihua Group offers customization options that allow clients to specify features such as lifting height, span, and control systems, ensuring that each crane meets the unique demands of its operational environment.

In addition to these giants, another noteworthy manufacturer is XCMG, which has gained recognition for its comprehensive portfolio of construction and lifting equipment. XCMG\u2019s LDP electric single beam cranes are designed with a focus on efficiency and safety, incorporating intelligent control systems that enhance operational precision. The company\u2019s dedication to sustainability is also reflected in its manufacturing processes, which prioritize eco-friendly practices. By offering customized solutions that align with the specific requirements of various industries, XCMG has positioned itself as a reliable partner for businesses looking to optimize their material handling operations.

| Number | Article Name |

| 1 | LD electric single beam crane |

| 2 | Universal gantry crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Moreover, the manufacturer Anshan Heavy Duty Mining Machinery Co., Ltd. has made significant strides in the crane manufacturing sector. Known for its robust engineering capabilities, Anshan specializes in producing heavy-duty lifting equipment, including LDP electric single beam cranes. Their products are engineered to withstand harsh working conditions, making them ideal for industries such as mining and construction. The company\u2019s focus on customization allows clients to select features that enhance the crane\u2019s functionality, ensuring that it can effectively meet the challenges of their specific applications.

As the demand for LDP electric single beam cranes continues to grow, these top Chinese manufacturers are at the forefront of innovation and customization. Their ability to deliver high-quality, tailored solutions not only meets the diverse needs of various industries but also contributes to the overall advancement of material handling technology. By prioritizing customer satisfaction and investing in research and development, these manufacturers are well-positioned to lead the market, ensuring that businesses have access to the most efficient and reliable lifting solutions available. In conclusion, the landscape of LDP electric single beam crane manufacturing in China is marked by a commitment to excellence, innovation, and customization, making these manufacturers key players in the global market.

How to Choose the Right LDP Electric Single Beam Crane Manufacturer in China

When considering the acquisition of an LDP electric single beam crane, selecting the right manufacturer is a critical step that can significantly influence the quality, performance, and longevity of the equipment. Given the vast array of manufacturers in China, it is essential to approach this decision with a clear understanding of the factors that contribute to a reliable and efficient partnership. First and foremost, it is advisable to conduct thorough research on potential manufacturers. This involves examining their reputation within the industry, which can often be gauged through customer reviews, testimonials, and case studies. A manufacturer with a solid track record is likely to provide not only high-quality products but also excellent customer service and support.

In addition to reputation, it is crucial to assess the manufacturer\u2019s experience and expertise in producing LDP electric single beam cranes. A company that has been in the industry for several years is more likely to have refined its processes and developed a deep understanding of the technical requirements involved in crane manufacturing. Furthermore, experienced manufacturers are often better equipped to handle customization requests, ensuring that the crane meets specific operational needs. This leads to the next important consideration: the ability to customize products. Since different industries have varying requirements, it is beneficial to choose a manufacturer that offers tailored solutions. This flexibility can include modifications in load capacity, span length, and additional features such as remote control systems or safety mechanisms.

Moreover, it is essential to evaluate the quality of materials and components used in the manufacturing process. High-quality materials not only enhance the durability of the crane but also ensure safety during operation. Therefore, manufacturers that adhere to international quality standards and certifications should be prioritized. This commitment to quality often reflects a manufacturer\u2019s dedication to producing reliable equipment that can withstand the rigors of daily use. In conjunction with material quality, it is also important to consider the technological advancements employed by the manufacturer. Modern cranes often incorporate advanced technologies that improve efficiency, safety, and ease of use. Manufacturers that invest in research and development are more likely to offer innovative solutions that can enhance operational productivity.

Another critical aspect to consider is the level of after-sales support provided by the manufacturer. A reputable manufacturer should offer comprehensive support services, including installation, maintenance, and training for operators. This support is vital for ensuring that the crane operates optimally and safely throughout its lifespan. Additionally, a manufacturer that provides readily available spare parts can significantly reduce downtime in case of repairs, further enhancing operational efficiency. Furthermore, it is advisable to engage in direct communication with potential manufacturers. This interaction can provide valuable insights into their customer service approach and responsiveness to inquiries. A manufacturer that is willing to engage openly and transparently is likely to foster a more collaborative and productive relationship.

Lastly, pricing should be considered, but it should not be the sole determining factor. While it is important to find a manufacturer that offers competitive pricing, the focus should remain on the overall value provided, which includes quality, customization options, and support services. By taking the time to evaluate these various factors, businesses can make an informed decision when selecting an LDP electric single beam crane manufacturer in China. Ultimately, the right choice will lead to enhanced operational efficiency and a successful long-term partnership.